We are proud to present the next step in development of the damping systems, namely, SS20 Gold suspension strut mounts, which introduces the innovative “Sliding damper” technology, using a unique sound-absorbing material (designed and patented by SS20) – Isolastan.

Which means considerable reduction of noise and vibrations generated by the motor car suspension due to use of the innovative Isolastan material.

Which is achieved by using SS20 bearing performed on the Russian roads (commercially produced for other SS20 mounts).

Which is achieved by the minimum radial displacement of the rod in the mount (less than 1 mm).

Strut design provides a 1” Caster increase that allows a vehicle to keep a path more accurately and requires less path correction. This helps to reduce driver's fatigue and the risk of accident when travelling a long distance. Wheel alignment in the arches does not change.

High reliability and durability – new patented material ISOLASTAN, which considerably surpasses rubber in elasticity at below-zero temperatures, and damper pull-out locking system construction guarantee perfect operation on any roads and in any climate conditions in Russia.

Regardless whether the strut mount was fitted by certified installer or independently by own resources. If a receipt has been lost, the warranty shall be provided by the date embossed in the strut mount housing.

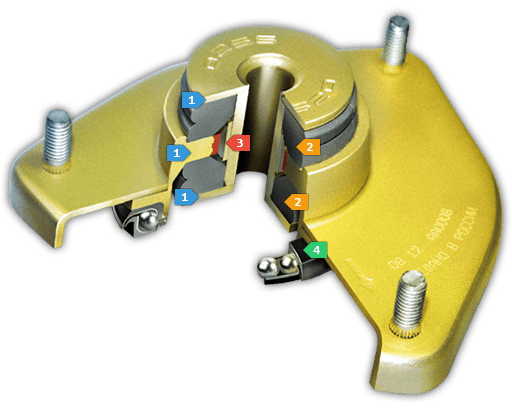

The strut mount consists of three main components: strut housing, damping element and internal bush to which the shock absorber piston is attached.

The effect of “sliding damper” is achieved by using a metal-PTFE guide. In the working suspension a chrome bush moves with the damper within this guide causing minimum friction — “slides”.

The damper is composed of two portions: the upper one works when the strut stop moves and the lower portion takes up load when the suspension is compressed. Thus, the new strut by SS20 uses a separate composite damper each portion of which takes up only compressive load applied downward or upward. In other struts a rubber damper works under a complex tension-compression load plus shear load.

The upper and lower damper portions are assembled in a package. There is a supporting pad of the housing between the halves of the damper. Damper cushions are forcibly held by upper and lower arresters. These arresters are joined by means of the chromium-plated bush. Thus, the damper is secured against ejection; therefore, the strut of such design shall never disappoint you.

Besides, the damping element of the strut is to take up the strut inclination when the steering wheel is turned. Ordinary rubber damper welded to the strut housing breaks and peels off. In SS20 Gold strut the damper components take up only compressive load, thus the service life of the elastic damper elements is getting longer and the damper avoids breaking and peeling. The upper and lower portions of the damper are not welded to the housing elements; therefore, damper peeling off the SS20 Gold strut housing may not occur.

There is a base plate between the damper parts. The damper plates are tightened by damper stops at the top and bottom which prevents the damper from splitting.

The upper part of the damper supports during downward motion. The lower part of the damper takes the load during compression (strut rod compression). Thus, there is a separate compound damper in this design, where each half reacts to compression from above or below. While the rubber strut of the damper takes the pressure of multiple loads of tension compression and horizontal shift.

The effect of “sliding damper” is achieved by using a metal-PTFE guide. In the working suspension a chrome bush moves with the damper within this guide causing minimum friction – “slides”

Complete with a highly reliable well-protected SS20 thrust bearing designed for load-sharing strut mounts, with good noise absorption and unconditional warranty.

Many manufacturers of automotive components intend to produce struts with the softest damper to make travelling in a motor car more comfortable, but this results in the increase of the radial displacement of the shock absorber piston on entering into a turn. It worsens control characteristics — when the steering wheel is applied (a soft damper works both axially and radially).

The metal fluoroplastic guide in the SS20 Gold strut is welded into the strut housing via monolithic polyurethane. The polyurethane layer ensures shock absorber piston swaying required for normal operation of the McPherson strut suspension and a minimum of 0.5 mm radial motion of the piston under 300 kg load. This particular small displacement of the piston in the SS20 Gold strut makes vehicle control precise and easy.

Please, focus your attention on the sliding element that we use in the SS20 Gold strut. It is borrowed from shock absorbers which our company manufactures on a commercial basis and of which reliability has been proved by faultless performance for many years. Polished chromium-plated surface slides over fluoroplastic thinly applied onto metal. It results in an ideal friction couple which according to specifications may work without lubrication under appreciable overload and within a wide temperature range.

One more advantage is displacement of the SS20 Gold strut damper as compared to the damper in a standard strut, which increases Caster angle by 1 degree. The greater Caster angle ensures more stable straight motion of an automobile without additional corrective steering actions. In turn the additional angle improves tire grip on the road surface; the steering wheel more readily returns into the neutral position, and wheels in the wells remain aligned.

The SS20 Gold strut is complemented with a proprietary SS20 high-reliability thrust bearing. The bearing cages are rubberized, which reduce transmission of vibrations and noise from suspension to the vehicle body. The bearing outline seal is similar to an engine packing gland and makes the bearing dust- and moisture-proof and protects it from abrasive particles as opposed to other bearings with plastic housings. Besides, SS20 bearing displays higher capacity as compared to the thrust bearing in a standard strut, and it is not affected by brinelling (indentation of radial grooves across races, which results in stick-slip steering wheel turning). Relubrication is not needed during the whole service life. Thus, we propose a reliable and well-protected thrust bearing for struts with load distribution that displays appreciable noise absorption and offer the absolute manufacturer's warranty.

Such load distribution makes it possible to attain high reliability and increase service life of all the suspension components.

SS20 designed and patented the strut mount with the distribution of load from vehicle mass and shock absorbers in 2001. The sliding damper with distribution of axial and radial loads has been developed and patented by SS20 in 2012.

We appreciate your confidence in our products, that is why all products produced by SS20 are subjected to strict quality control and are provided with the manufacturer's warranty.